WE DEVELOP AND PRODUCE FINISHED GOODS IN OUR OWN FACILITIES RESULTING IN CONSISTENT AND CONTROLLED QUALITY.

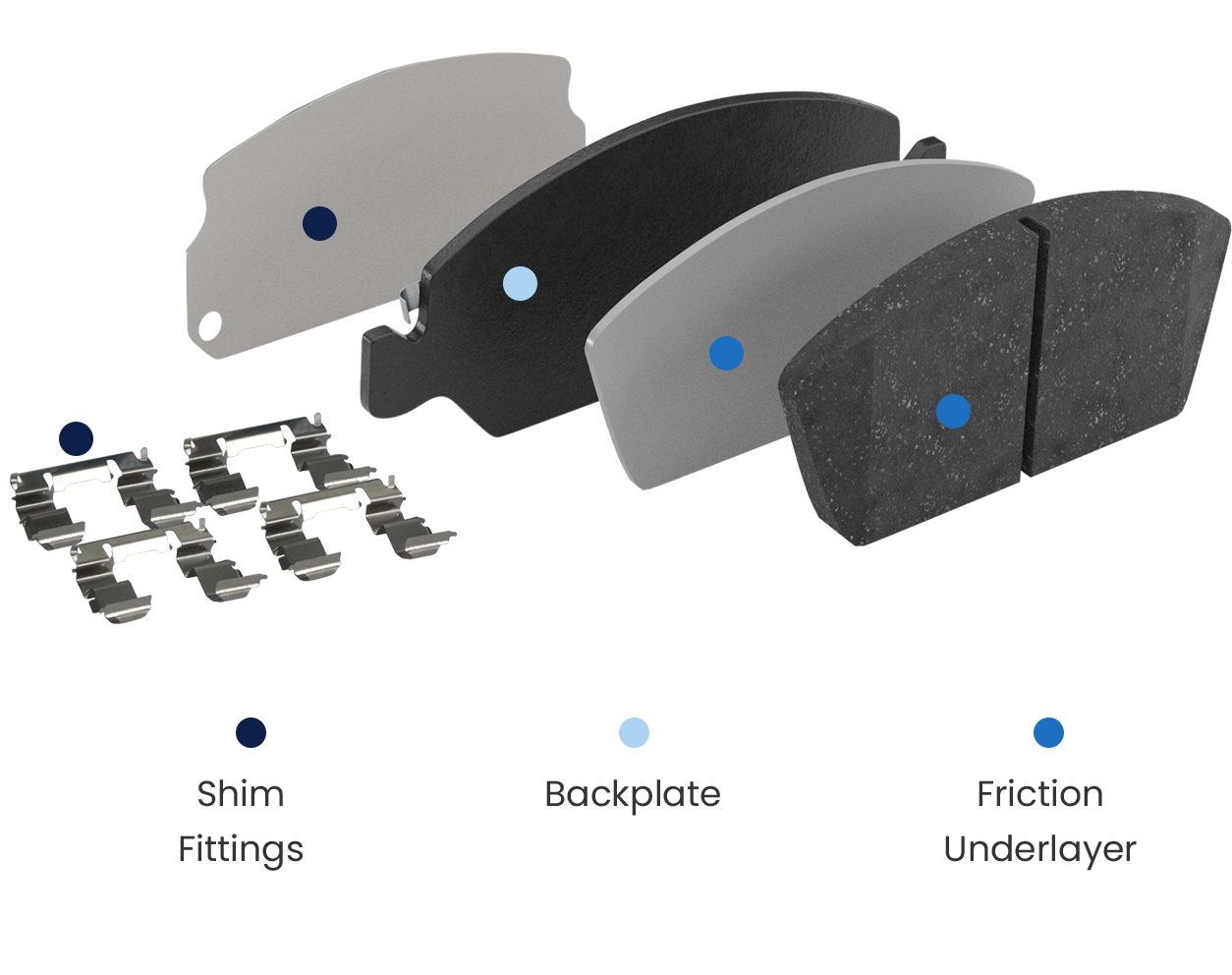

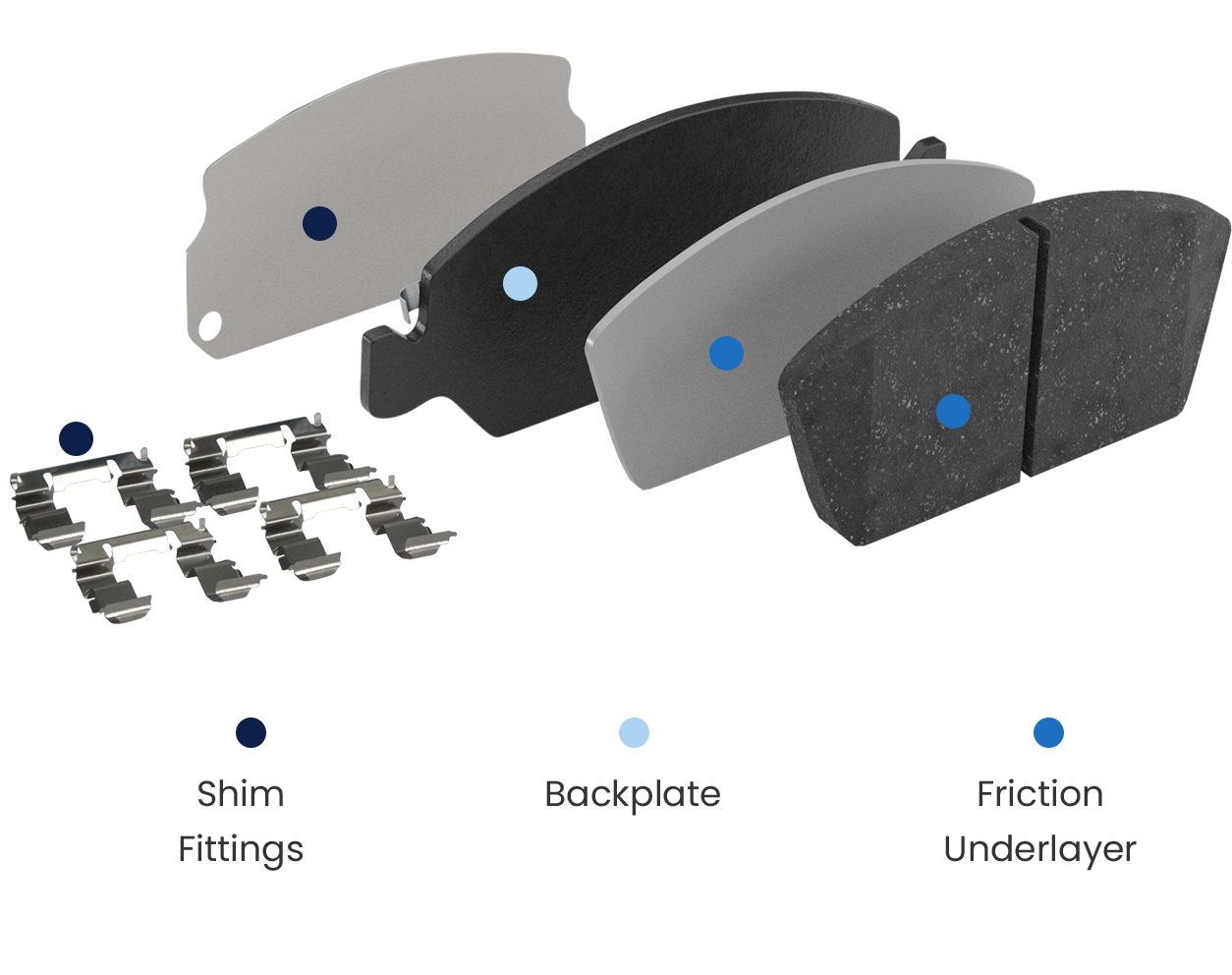

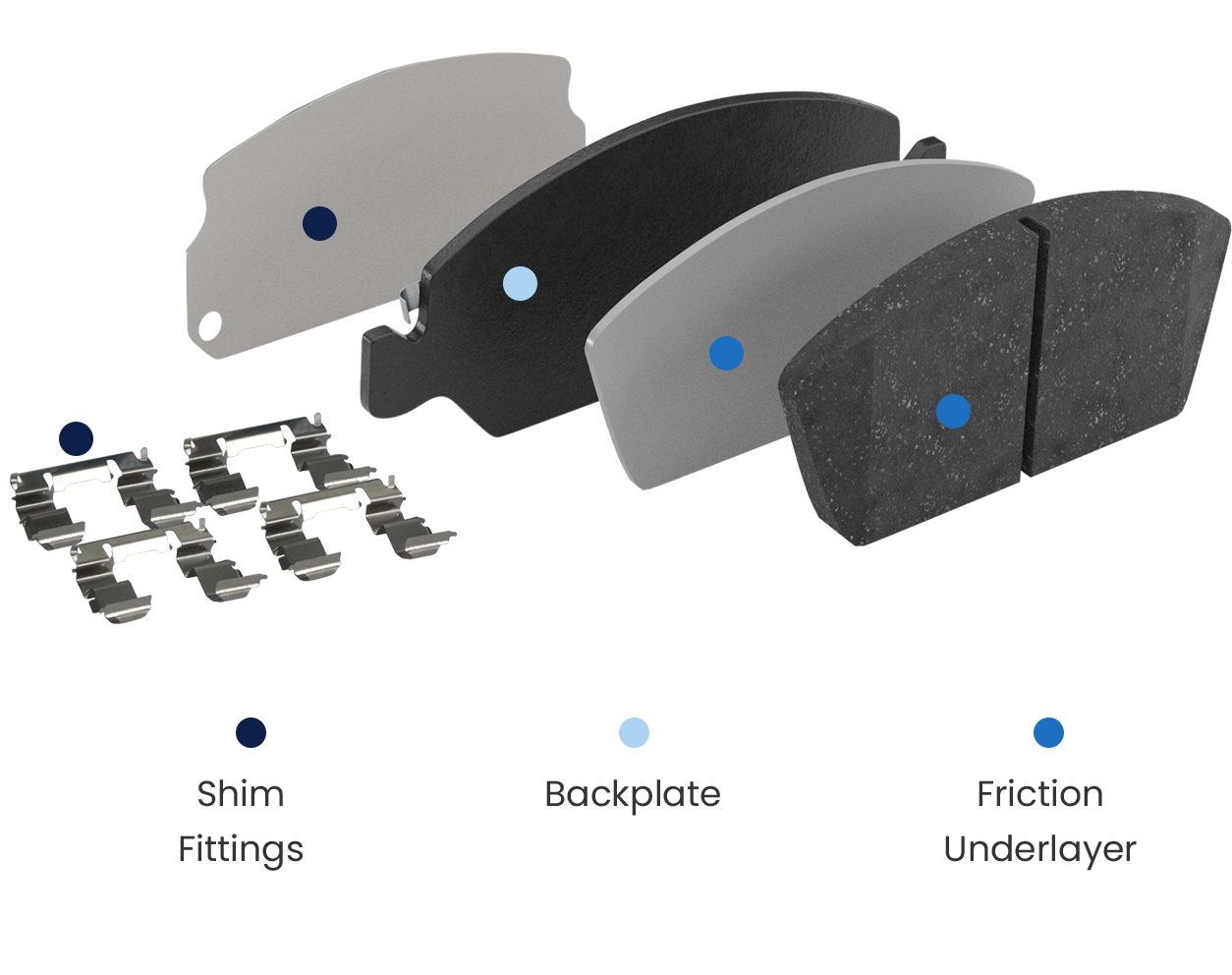

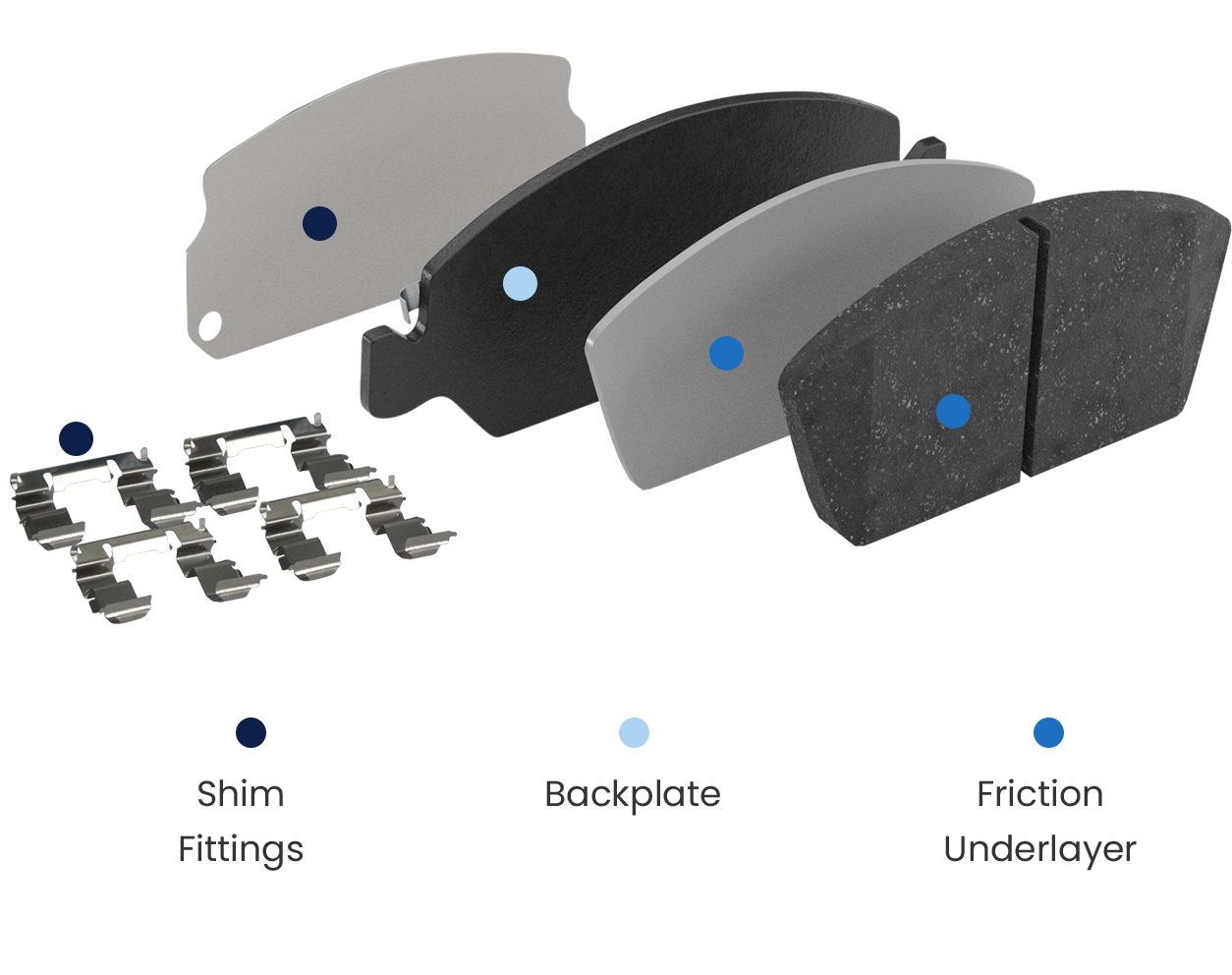

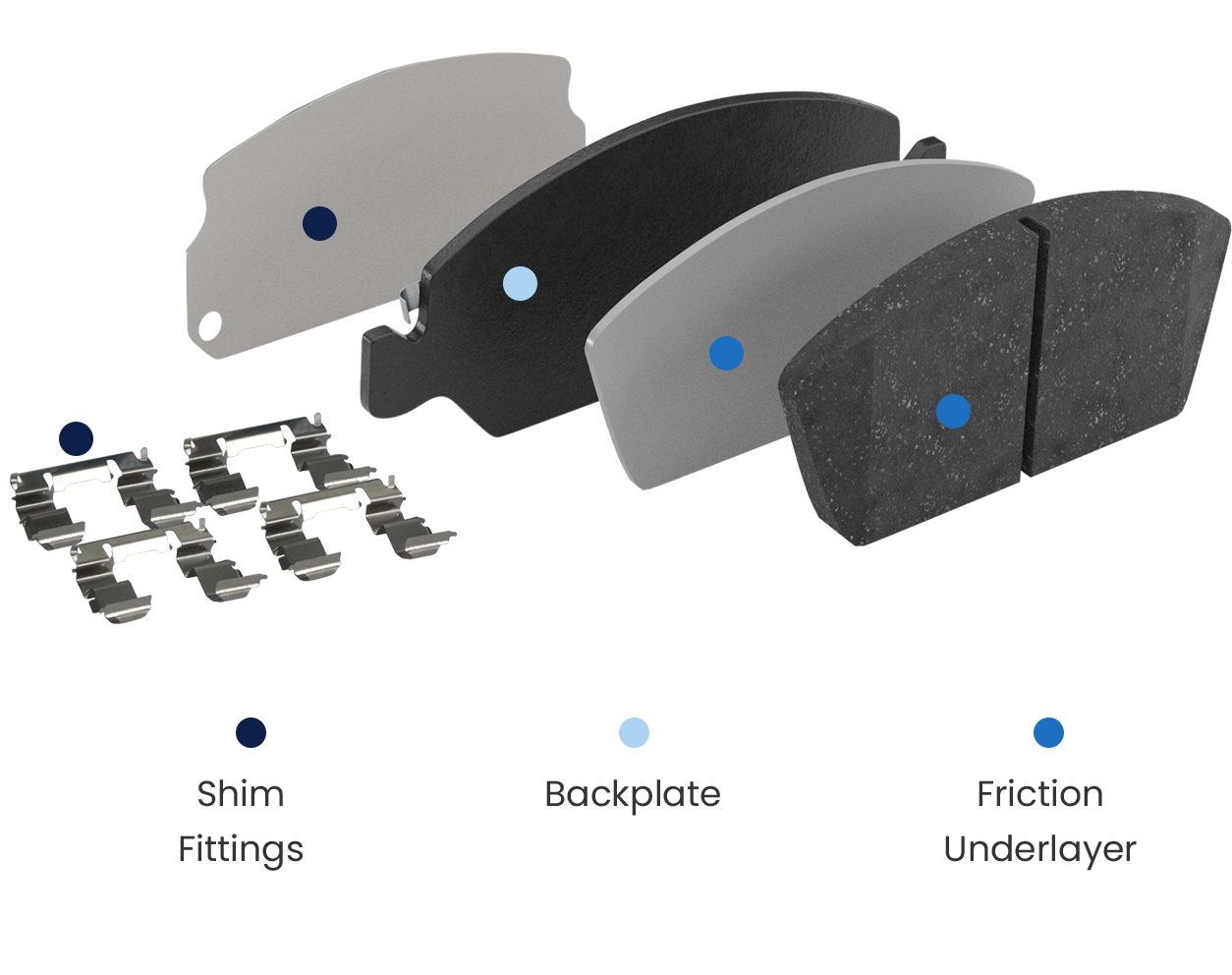

Bendix passenger vehicle brakes are manufactured by MAT Holdings, Inc., a global supplier of brake products. MAT Holdings’ friction companies are vertically integrated, meaning we design, manufacture, and test all system components of the brake pad including shims, backing plates, friction materials, hardware, and brake rotors. This allows MAT to control the quality, production & delivery, and ultimately the superior value you receive with Bendix products.

Our engineers view design of the brake pad and rotor holistically as well as individually, with a mindset of continuous improvement as it applies to each vehicle. Providing OE and OES solutions on global platforms across 3 continents, we leverage our knowledge base, tailoring Bendix products to the needs of the aftermarket. This approach creates "first to market" opportunities with the appropriate solution for the application.

WE DEVELOP AND PRODUCE FINISHED GOODS IN OUR OWN FACILITIES RESULTING IN CONSISTENT AND CONTROLLED QUALITY.

Bendix passenger vehicle brakes are manufactured by MAT Holdings, Inc., a global supplier of brake products. MAT Holdings’ friction companies are vertically integrated, meaning we design, manufacture, and test all system components of the brake pad including shims, backing plates, friction materials, hardware, and brake rotors. This allows MAT to control the quality, production & delivery, and ultimately the superior value you receive with Bendix products.

Our engineers view design of the brake pad and rotor holistically as well as individually, with a mindset of continuous improvement as it applies to each vehicle. Providing OE and OES solutions on global platforms across 3 continents, we leverage our knowledge base, tailoring Bendix products to the needs of the aftermarket. This approach creates "first to market" opportunities with the appropriate solution for the application.

WE DEVELOP AND PRODUCE FINISHED GOODS IN OUR OWN FACILITIES RESULTING IN CONSISTENT AND CONTROLLED QUALITY.

Bendix passenger vehicle brakes are manufactured by MAT Holdings, Inc., a global supplier of brake products. MAT Holdings’ friction companies are vertically integrated, meaning we design, manufacture, and test all system components of the brake pad including shims, backing plates, friction materials, hardware, and brake rotors. This allows MAT to control the quality, production & delivery, and ultimately the superior value you receive with Bendix products.

Our engineers view design of the brake pad and rotor holistically as well as individually, with a mindset of continuous improvement as it applies to each vehicle. Providing OE and OES solutions on global platforms across 3 continents, we leverage our knowledge base, tailoring Bendix products to the needs of the aftermarket. This approach creates "first to market" opportunities with the appropriate solution for the application.

WE DEVELOP AND PRODUCE FINISHED GOODS IN OUR OWN FACILITIES RESULTING IN CONSISTENT AND CONTROLLED QUALITY.

Bendix passenger vehicle brakes are manufactured by MAT Holdings, Inc., a global supplier of brake products. MAT Holdings’ friction companies are vertically integrated, meaning we design, manufacture, and test all system components of the brake pad including shims, backing plates, friction materials, hardware, and brake rotors. This allows MAT to control the quality, production & delivery, and ultimately the superior value you receive with Bendix products.

Our engineers view design of the brake pad and rotor holistically as well as individually, with a mindset of continuous improvement as it applies to each vehicle. Providing OE and OES solutions on global platforms across 3 continents, we leverage our knowledge base, tailoring Bendix products to the needs of the aftermarket. This approach creates "first to market" opportunities with the appropriate solution for the application.

WE DEVELOP AND PRODUCE FINISHED GOODS IN OUR OWN FACILITIES RESULTING IN CONSISTENT AND CONTROLLED QUALITY.

Bendix passenger vehicle brakes are manufactured by MAT Holdings, Inc., a global supplier of brake products. MAT Holdings’ friction companies are vertically integrated, meaning we design, manufacture, and test all system components of the brake pad including shims, backing plates, friction materials, hardware, and brake rotors. This allows MAT to control the quality, production & delivery, and ultimately the superior value you receive with Bendix products.

Our engineers view design of the brake pad and rotor holistically as well as individually, with a mindset of continuous improvement as it applies to each vehicle. Providing OE and OES solutions on global platforms across 3 continents, we leverage our knowledge base, tailoring Bendix products to the needs of the aftermarket. This approach creates "first to market" opportunities with the appropriate solution for the application.

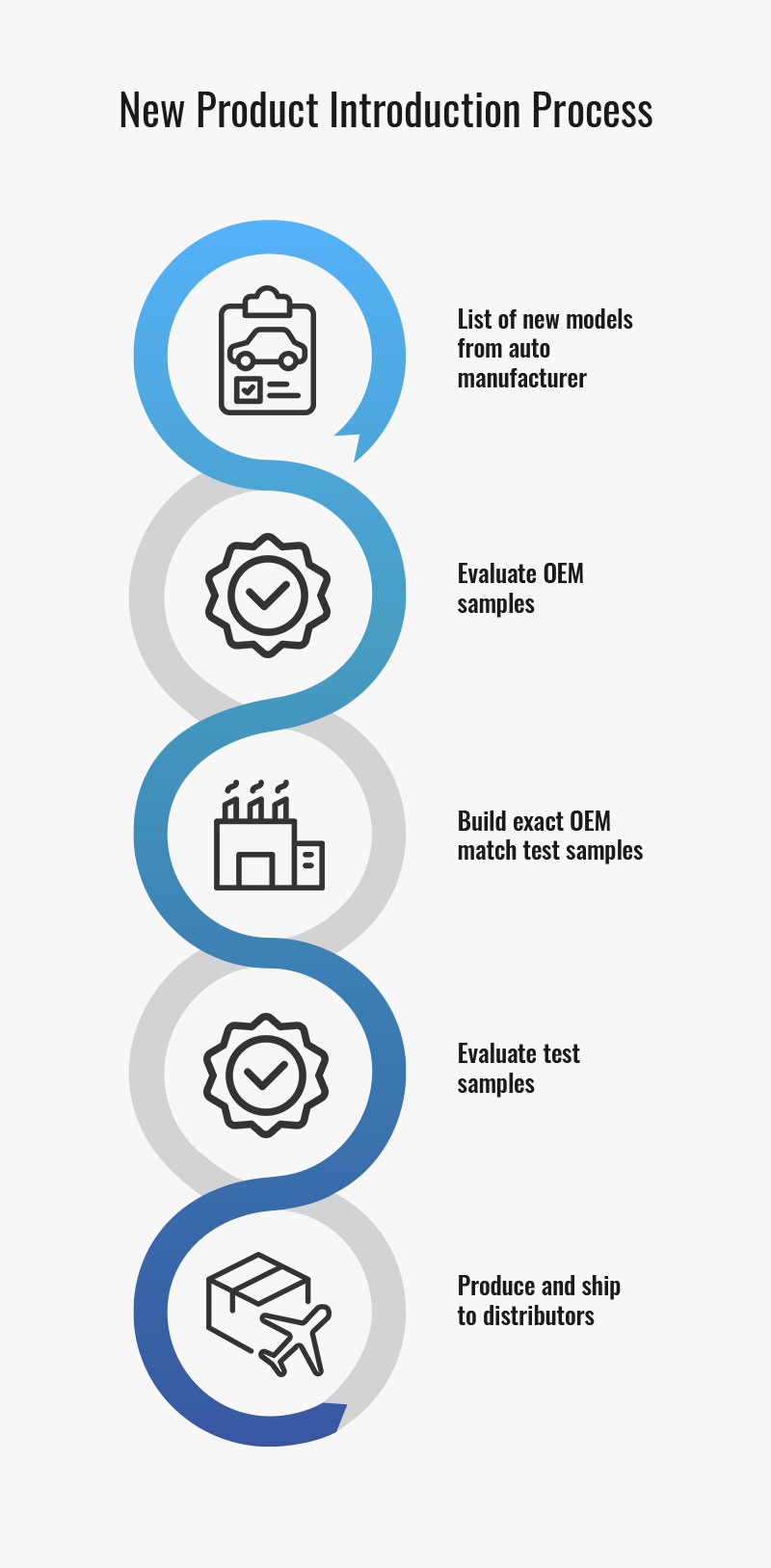

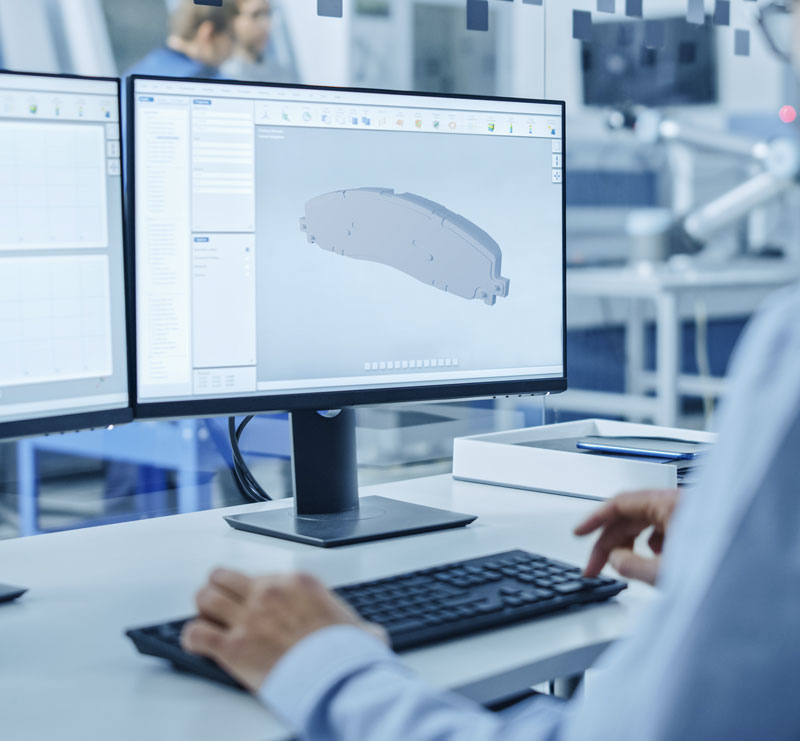

BENDIX PROVIDES INDUSTRY LEADING FIRST TO MARKET COVERAGE UTILIZING THE LATEST OE INFORMATION RELEASES.

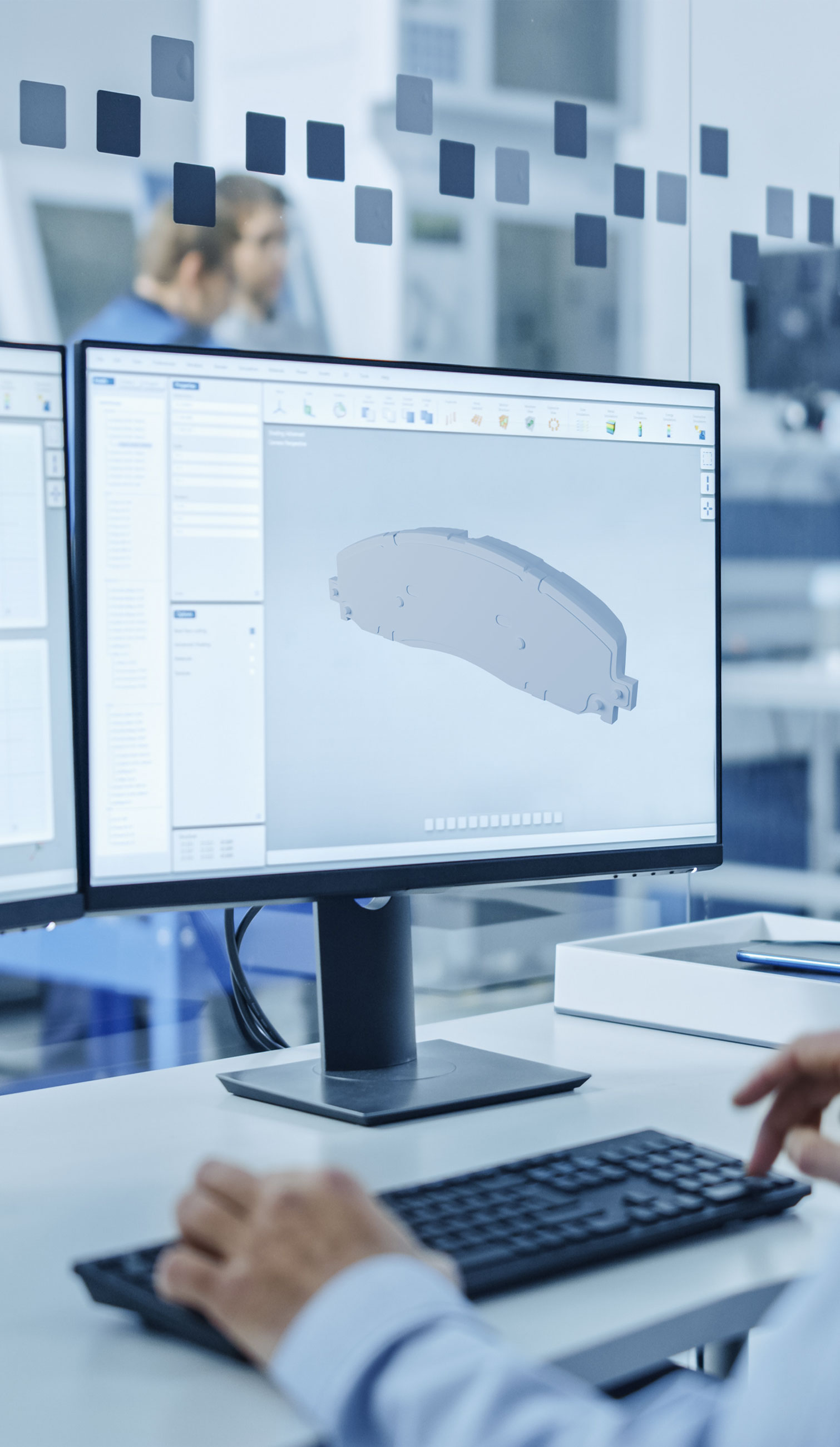

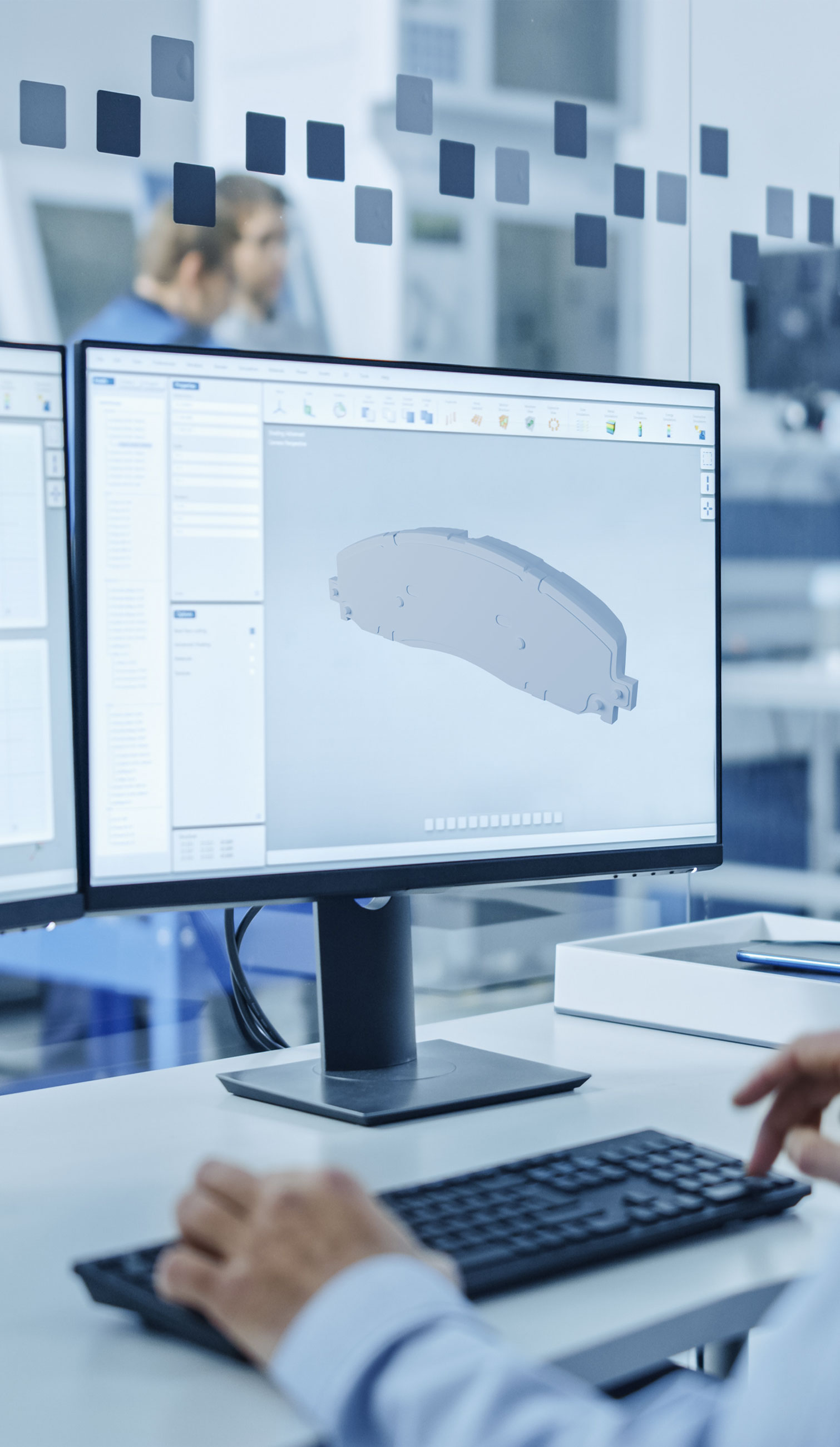

Our vertically integrated manufacturing system streamlines the OEM product duplication process without sacrificing quality.

We evaluate OE brake pad materials as well as the height tolerance of the back plate, the damping characteristics of shim materials, and the coefficient of friction among other criteria. Our design team will look at our database of materials to match the OE product. If there isn't a precise match, our R&D team will develop a new friction formula. And our shim division will match the shim, backplate and hardware.

BENDIX PROVIDES INDUSTRY LEADING FIRST TO MARKET COVERAGE UTILIZING THE LATEST OE INFORMATION RELEASES.

Our vertically integrated manufacturing system streamlines the OEM product duplication process without sacrificing quality.

We evaluate OE brake pad materials as well as the height tolerance of the back plate, the damping characteristics of shim materials, and the coefficient of friction among other criteria. Our design team will look at our database of materials to match the OE product. If there isn't a precise match, our R&D team will develop a new friction formula. And our shim division will match the shim, backplate and hardware.

BENDIX PROVIDES INDUSTRY LEADING FIRST TO MARKET COVERAGE UTILIZING THE LATEST OE INFORMATION RELEASES.

Our vertically integrated manufacturing system streamlines the OEM product duplication process without sacrificing quality.

We evaluate OE brake pad materials as well as the height tolerance of the back plate, the damping characteristics of shim materials, and the coefficient of friction among other criteria. Our design team will look at our database of materials to match the OE product. If there isn't a precise match, our R&D team will develop a new friction formula. And our shim division will match the shim, backplate and hardware.

BENDIX PROVIDES INDUSTRY LEADING FIRST TO MARKET COVERAGE UTILIZING THE LATEST OE INFORMATION RELEASES.

Our vertically integrated manufacturing system streamlines the OEM product duplication process without sacrificing quality.

We evaluate OE brake pad materials as well as the height tolerance of the back plate, the damping characteristics of shim materials, and the coefficient of friction among other criteria. Our design team will look at our database of materials to match the OE product. If there isn't a precise match, our R&D team will develop a new friction formula. And our shim division will match the shim, backplate and hardware.

BENDIX PROVIDES INDUSTRY LEADING FIRST TO MARKET COVERAGE UTILIZING THE LATEST OE INFORMATION RELEASES.

Our vertically integrated manufacturing system streamlines the OEM product duplication process without sacrificing quality.

We evaluate OE brake pad materials as well as the height tolerance of the back plate, the damping characteristics of shim materials, and the coefficient of friction among other criteria. Our design team will look at our database of materials to match the OE product. If there isn’t a precise match, our R&D team will develop a new friction formula. And our shim division will match the shim, backplate and hardware.